|

During the last few decades, the utilization of metal and steel for art sculpture has become progressively more popular. We see them outside government schools, buildings, malls, and other public spaces. Mirror-polished stainless-steel sculptures are very well known in public art projects because of their adaptable fabrication, alluring finishing, and exceptional capacity to resist UV damage and weather corrosion. Not just are the outcomes of custom metal sculpture fabrication exceptional and lovely, however the durability, malleability, and relative reasonableness of most metals have brought about numerous architects utilizing them to make beautifying sculptures for a wide range of design projects. In this blog, we'll clarify how they are fabricated in shops. How Is Custom Metal Sculpture Fabrication Done? Albeit the word sculpture’ summons pictures of a singular artist making wizardry out of a large block of marble, the custom metal sculpture fabrication process has many moving parts and will in general be a collaboration including engineers, architects, and metal fabrication experts. The process starts by styling your steel. Utilizing software with CAD and CAM combination, design experts make 2D profiles of the different pieces that will ultimately form the completed sculpture. Then, at that point, the proper material is chosen, with corrosion resistance being a fundamental component for welded metal artwork that will be put outside. Despite the fact that there are various ways of cutting the metal parts for use in a sculpture, computer numerical control (CNC) plasma cutters support more noteworthy accuracy and more exact outcomes. They are associated with a computer, which is outfitted with the previously mentioned design software and coordinates the plasma torch along the ideal toolpath. The cutter utilizes concentrated electrical currents to slice through electrically conductive metals while high-velocity gas eliminates the melted material from the space, guaranteeing a cleaner cut. Contingent upon the ideal result, the cut metal would then be able to be shaped utilizing at least one of the accompanying fabrication innovations.

Assuming appropriately fabricated, metal sculptures will endure for the long haul in basically all climate conditions. In the event that you are an architect, your task will accomplish the best outcomes assuming you work with a custom metal fabricator with the bits of knowledge and experience required to transform a useful material like metal into a lovely masterpiece. Pierre Riche - The Metal Sculpture Fabrication Expert Pierre Riche is known for his best welded metal artwork since 1992. Pierre endeavours to make the most exciting and unique sculpture, functional art and welded metal artwork conceivable. At Pierre Riche Art, our metal shaping abilities incorporate custom metal sculpture fabrication for architects and other design experts. By talented use of welding, cutting, heating, hammering, and finishing processes. we make custom sculpture that accurately match the proposed vision of your unique request. We have dealt with many sculptures and can deal with projects that require the accompanying:

0 Comments

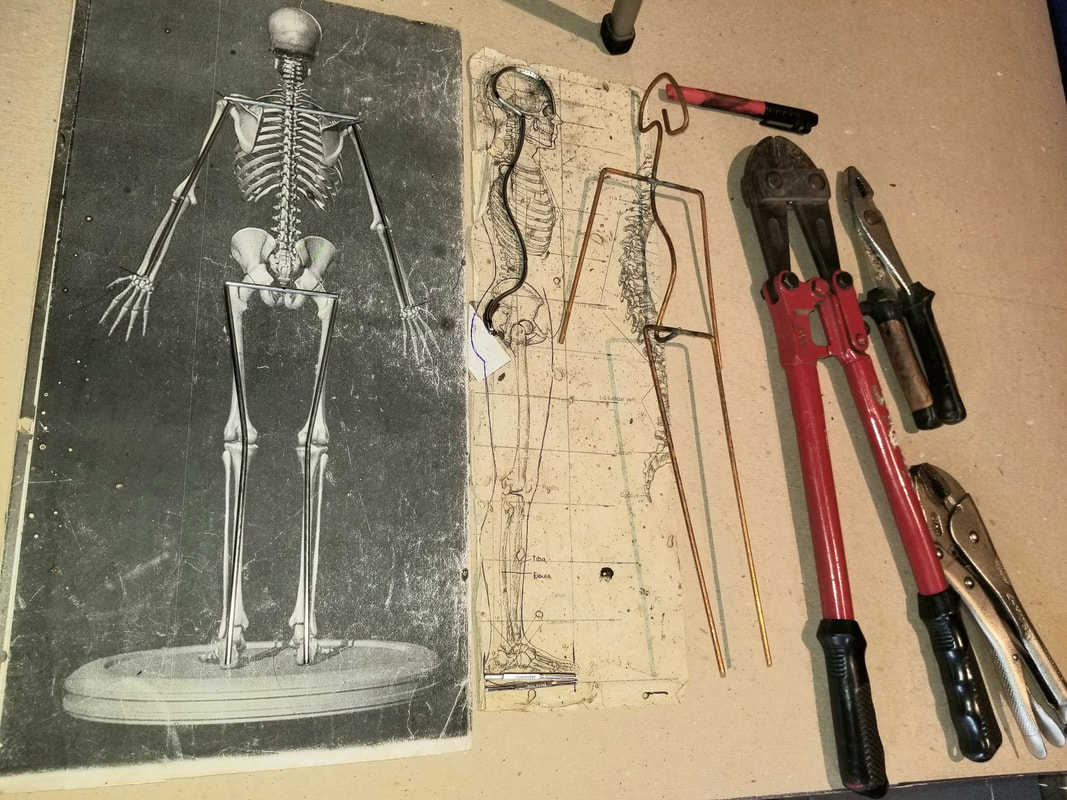

Whether it's a stainless steel or mild steel welded metal figure sculpture I'm starting, it all begins with the armature. It's very helpful to have accurate anatomical measurements for the bone structure. It will look awkward if this is not done right.

I TIG weld the stainless, which is very finicky to get to weld. the steel gets oxyacetylene welded which is fairly easy but took allot of practice. |

BlogArchives

September 2023

Categories

All

|