|

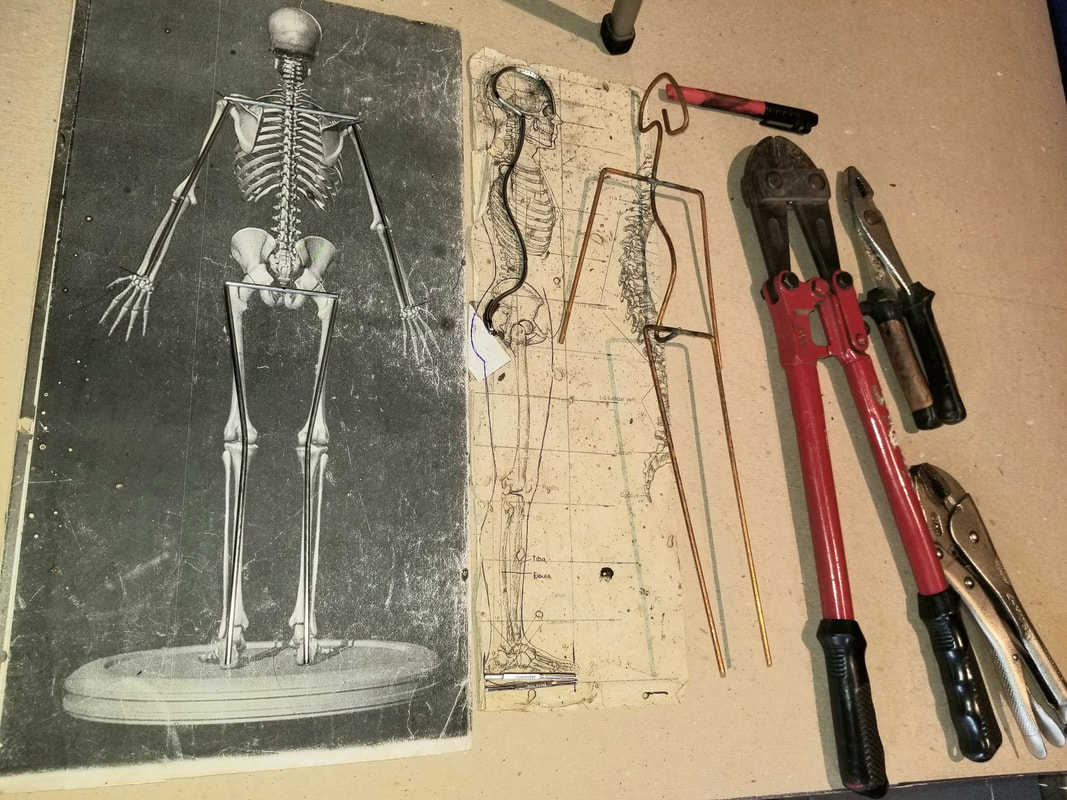

Whether it's a stainless steel or mild steel welded metal figure sculpture I'm starting, it all begins with the armature. It's very helpful to have accurate anatomical measurements for the bone structure. It will look awkward if this is not done right.

I TIG weld the stainless, which is very finicky to get to weld. the steel gets oxyacetylene welded which is fairly easy but took allot of practice.

0 Comments

Sierra Azul plant nursery holds a jurried sculpture show every year. They always have a beautiful plack made with the local newspaper article on it. My sculpture "The Crown She Wears" was featured in it.

Here you see a new sculpture being started. There is about 2 hrs work done. I have developed the habit of diligently clocking my sculpting time so I can look back when it is finished to see how long it actually took to make.

The computer screen shows my subject matter. I am careful not to shoot hot metal onto the screen and damage it. I have used the MIG welder and oxyacetylene welding torch here to suggest movement, muscle and mass as I build up the material. The first application of material is crude and bulky held together with tack welds. The next phase is to use the torch. by making the metal parts red hot and ductile I can bend in, twist, hammer and shape the form to resemble the character I'm looking for, The foot or base of the pose must be strong enough to withstand the manipulation to come. |

BlogArchives

September 2023

Categories

All

|